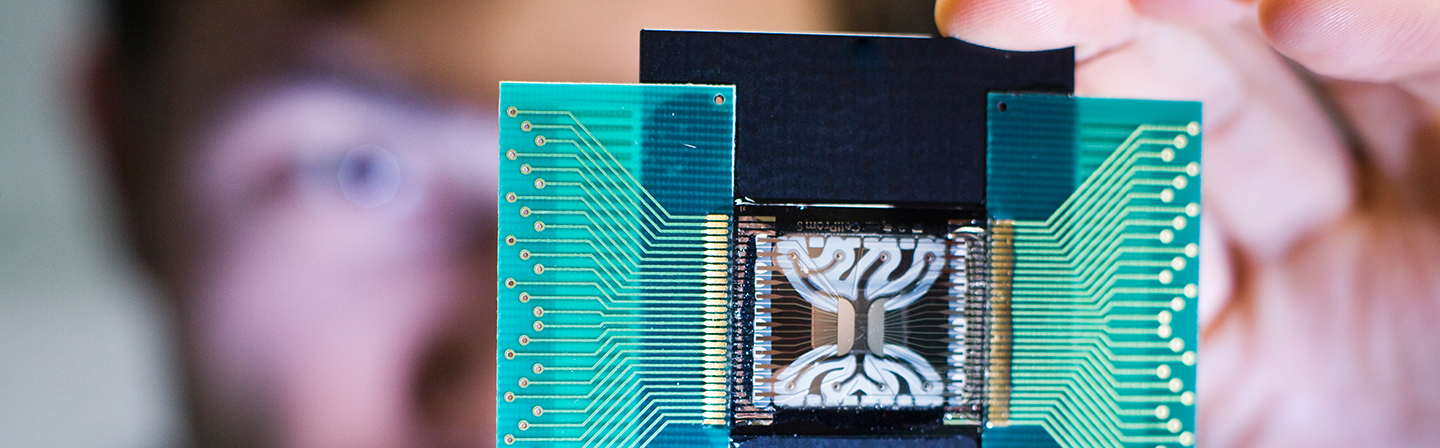

Cell culture, cell culture monitoring, cell culture expansion – these are all typical processes in a laboratory and yet are not being sufficiently automated, because the individual requirements of the cultures can vary enormously, depending on their source. At times, not all of the parameters will be known, which makes more frequent checks and manual intervention necessary. Automation in a feedback loop with intense, automated observation of the cultures may be the solution to this problem, and provide a basis for laboratory results that can be reproduced with better accuracy.

Applications suitable for automated customized solutions include monotonous operations right through to flexible processes in the laboratory and in production. Established work steps or devices can be integrated into the solution with the same ease as specific work materials, ensuring that a change of system can be avoided. Furthermore, automated processes are easier to have certified.

We provide the following services as solutions for complex laboratory automation tasks:

- Software development

- Creation of feasibility studies

- Development, design and construction of everything from prototypes to turnkey appliances and machines

- Production development and small-scale series for surface modification processes, including differentiation-based plasma treatment

Fraunhofer Institute for Cell Therapy and Immunology, Branch Bioanalytics and Bioprocesses IZI-BB

Fraunhofer Institute for Cell Therapy and Immunology, Branch Bioanalytics and Bioprocesses IZI-BB